B series / T series

|

|||||||||

Features

| Automation of DIP solder fillet inspection and data management |

|

| Improvement of soldering quality |

|

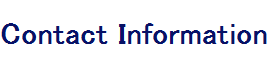

Eliminate the mechanical and human-caused stress of flipping PCB, and improve the long-term reliability.

|

|

| High productivity by simplified production line |

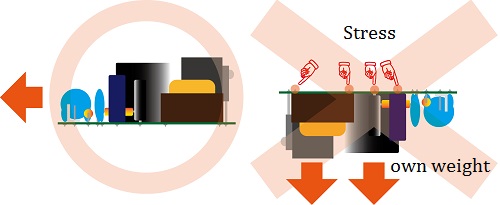

Eliminate the board flipping process

-

Simplify and space saving of production line

(Possible to save 500mm space when you inspect middle size PCB) -

Energy saving without board flipper

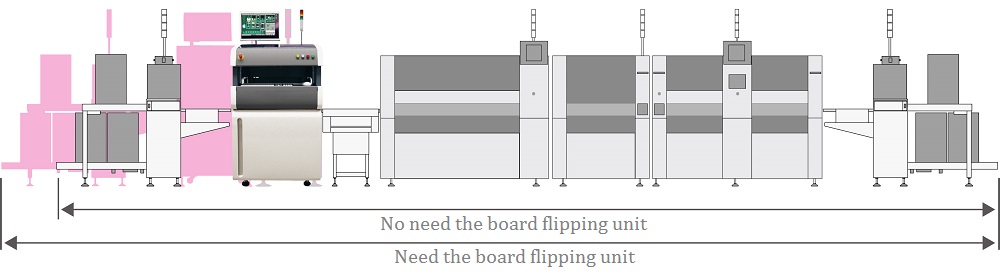

| Three types of installation ways |

Modular type T series can be integrated to bottom or top of conveyer or both sides according to the application.

For example, installation is possible for every process including the bottom inspection of solder joints post soldering or both side inspection of components surface/solder status.

Specification

| Model Name | U22XB-350L | T22XB-350 | T22XB-550 |

| External Dimension (mm) | W878 D916 H1313*1 | W700 D880 H316*2 | W900 D1082 H316*2 |

| Weight | 210kg | 50kg | 75kg |

| Power Supply | AC100V - 240V | AC100V - 240V | AC100V - 240V |

| Power Consumption | 700W (Incl. PC) | 300W (Incl. PC) | 300W (Incl. PC) |

| Operating Environment | 15-30℃ 15-80%RH (No Condensation) |

15-30℃ 15-80%RH (No Condensation) |

15-30℃ 15-80%RH (No Condensation) |

| Movement Type | X-Y axis: By camera X axis PCB Fixed |

X-Y axis: By camera | X-Y axis: By camera |

| Motor | Servo Motor x3 | Servo Motor x3 | Servo Motor x3 |

| Position Repeatability | <±0.05mm | <±0.05mm | <±0.05mm |

| Max. Speed | 720mm/sec | 750mm/sec | 750mm/sec |

| Max. PCB size | Max:350×250 mm Min:50×50 mm |

350×260 mm | 550×460 mm |

| PCB Fixing Method | PCB Top Clamping | - | |

| PCB Thickness | 0.6-2.0mm | - | |

| PCB Weight | 1.0kg | - | |

| Clearance | Top Clearance:60mm Bottom Clearance:20mm |

- | |

| Conveyer Speed | 10-500 mm/sec | - | |

| Camera | 5 Mega-pixel Top Camera + 8 Side Cameras(Option) | ||

| Lens | Telecentric Lens | ||

| Lighting System | White Light + Side Red Light + Diffuse-On Axis LED or RGB LEDs + Diffuse-On Axis LED (Select at point of purchase) |

||

| Inspection Algorithm | Pattern Matching / Histogram | ||

| Inspection Stages | SPI/Post CIP, Pre and post (re)flow | ||

| Inspection Targets | Chip components, QFP,Axial components, IC, etc. | ||

| Component Inspection | Presence, Shifting, Angle offset, Position detection, Polarity, Correctness, Bridges, Soldering, Solder ball, Alien substance, NG pattern matching, Sampling, Scratch, Smearing, Crack,Bridges of flow PCB, Slit width |

||

| Solder Paste Inspection | Shifting, Smearing, Blurring, Bridges | ||

| TOP FoV | 36×30 mm (Resolution:15μm) | ||

| SIDE FoV | Approx. 6×6 mm (Resolution:13μm) | ||

| Z axis Stroke | +28mm, -2mm | ||

| Inspection Speed | Approx. 0.3sec/point (Depends on PCB type) | ||

| *1: H2,000mm including worning tower light *2: H360mm including protrusions |

|||

Please note that above specification is subject to change without notice.

Please be sure to confirm the updated specification at the time of purchase.

Downloads